OK some thoughts for you to consider, that worked for me:

First I would change how you look at your VE table - top axis should be MAP kPa (metric), the numbers/data should be "grams/cylinder" (aka speed-density) instead of percent VE. Once you've done that, THEN take a look at the shape of your main VE table...

Lots of calibrators sell smoothed VE tables; personally I keep the peaks and valleys, WITHIN REASON. The VE table you posted is scary, and undoubtedly incorrect because no engine I can imagine would process air that way in reality; if the VE map arrived that way from the AutoVE process then I would recheck the math in your calculated PIDs, feed from your wideband, BENS PID, data filters, etc. The data filters are *critical*, you cannot get anything reasonable if you are making fueling corrections from the wrong data in the log! Likewise, you need to make doubly sure that during the AutoVE process you have disabled DFCO/PE, checked commanded fuel, disabled the MAF etc etc etc to truly put the PCM in speed-density mode before logging.

It was explained to me that the reason against a jagged VE table is because: during operation if the PCM wanders from a 'smooth' cell to a 'peaky' cell it will errantly think the motor has just swallowed a huge gulp of air when in reality it actually hasn't - the PCM "panics" because of this falsely calculated massive air change, and responds with all kinds of spark nonsense like burst knock retard, torque management, etc etc etc. I was given a specific number, my memory says it was either 3% or 5% meaning that in a 'sane' VE table one should see values in neighboring cells within 3-5% of each other. Give or take, use your judgment.

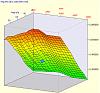

I am learning that it is more important to give the motor "what it wants" rather than a sexy, overly-smoothed mathematical model - when I had a smoothed VE table, the vehicle performed worse, got 20% worse MPG, was doggy of the line. After letting AutoVE take it's course, my VE table has prominent dips at 2000-RPM and 2800-RPM (see attached, these dips look like accordion folds in a map), these dips are not big but they're certainly present because when I try to smooth them out by hand the wideband and the truck's performance reveals them as legitimate; I explain this to myself as an effect of the headers/exhaust/intake plumbing design (resonant frequencies, helmholtz effect, airflow dynamics, blah blah blah, who knows!...) but it's obvious that this is the map of airflow in this application. With the slight peakiness present my MPG went way up, the vehicle is an animal to drive (!), it just "runs right" and does not have KR etc, the average MAP reading during cruise is lower (the motor has much more manifold vacuum at cruise) etc all signs of a happy motor.

I would double-check your tuning setup, and then go ahead and somewhat smooth the VE table (or start from your stock one) and begin the AutoVE process. It will take a few repeats of the AutoVE process with you smoothing on each iteration; after the map is within +- 4% of it's final shape, you will discover that smoothing is probably not necessary anymore, and you can let nature take it's course as the map settles into its final shape. The point is not to arrive at a sexy smoothed formulaic 3D graph - rather the point is to accurately map the airflow consumption through the engine!

Since I've gone this far, a couple more things I've discovered: the AutoVE tutorial recommends that once you get fueling to within 1-2% of ideal you're done; I've been able to achieve fueling to within +- 0.15% (it took many iterations of AutoVE and a great wideband), and the result was a major increase in MPG, and substantial reduction in part-throttle KR. I've seen KR eliminated by correcting a slight rich condition (-0.5 AFR) and did not have to touch the spart tables. Running a little rich will induce KR! Last discovery I've made, when you modify timing the motor will respond by running rich or lean - when you change timing, you will find your fueling is off 1-2% again in the affected cells, necessitating follow-up correction (AutoVE). Changes in spark timing affects fueling, so my best practice is a sequence of AutoVE first, then once the main VE table is pretty "solid" I will start shaping timing, then go back and do a follow-up round of AutoVE again. In my case I bought a "Starter Tune" from a reputable guy in the EFILive community, and was able to massage it from there.

A lot to digest, hope this experience helps.

- Steve

PS - sorry to read that you have had so much trouble, that is what takes the fun out of a project like this. And whoever told you "it's not tunable" was speaking soley for himself.