That's only an 8% spread, so compression is ok... what about leakdown...?

Are you losing coolant...?

What is fuel rail pressure...?

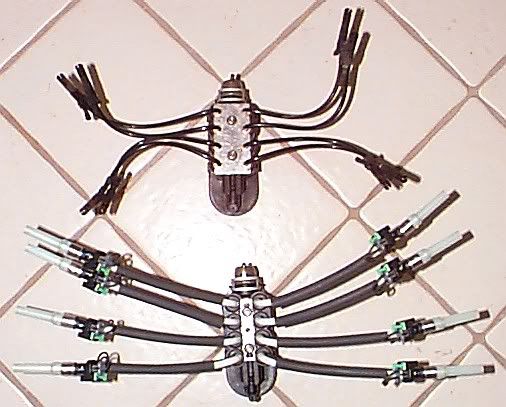

Do plug wires and coils pass the dark test (external arcing when viewed in darkness)...?

Does MAP follow vacuum hand pump (while viewing on scantool)...?

Does TP follow throttle movement (while viewing on scantool)...?

What are LTFT''s and wideband AFR when problem occurs...?

Do you have a log file...?

Reply With Quote

Reply With Quote