I have noticed that looking at many big cam dyno sheets that there is almost always a dip in torque from ~2000 rpm to ~3200 rpm. There is evidence that this is a physical characteristic of the engine. I just got done mapping my VE table, which is accurate to 0.5%. As many of you already know, VE is correlated to torque. If you view the VE table as VE vs. RPM with lines of constant MAP you'll see the general shape of your torque curve.

I have an MS4 cam in my car. Here are some specs: 239/242, .649"/.609", 111 LSA.

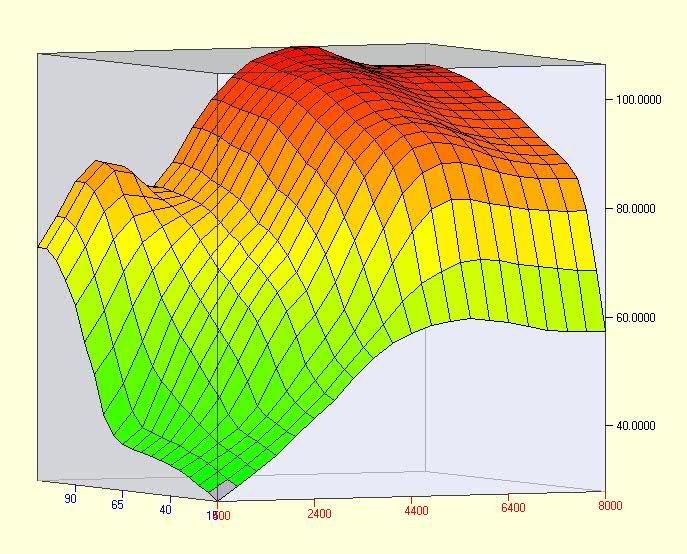

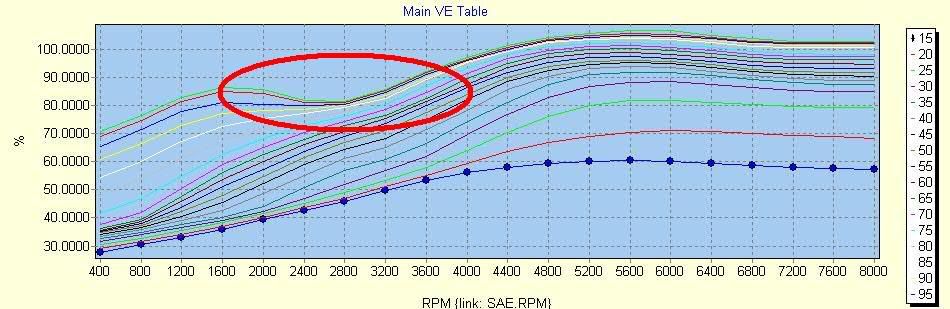

Here is my VE table both as a map, and as table data.

Map

Table Data - I have circled in red the dip in the VE table, which will also likely be a dip in the torque curve. This characteristic seems to be fairly normal for a cam of this size.

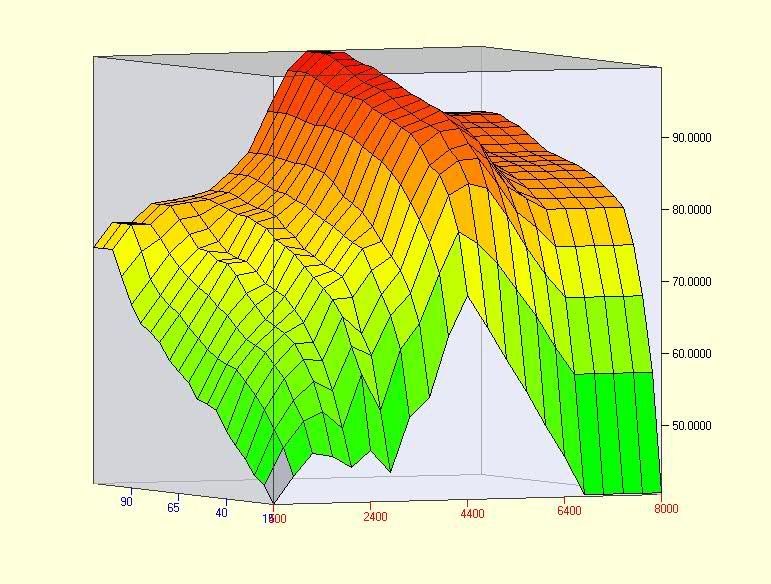

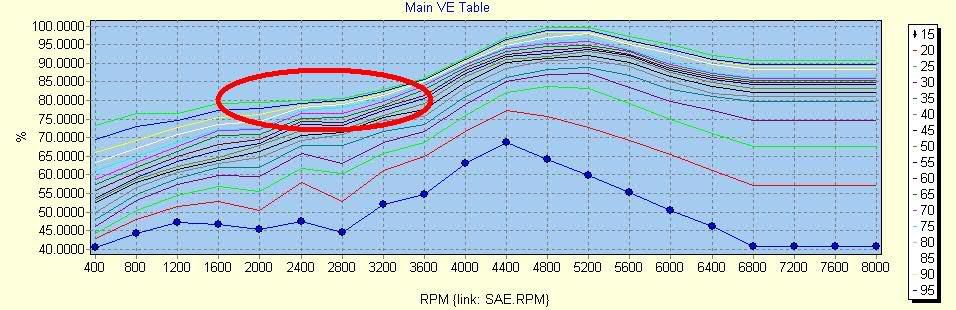

Then I started looking at stock tunes. I have done a comparison of a 2002 Z06 tune. I noticed similar behavior, and it looks like GM took some measures to reduce this behavior. I'll show what I think they did in a minute.

The Z06 VE map:

The Z06 table - Note the circled red flat. The Z06 cam is smaller, so it looks like this shows up as a flat as oppposed to a dip, but its still there.

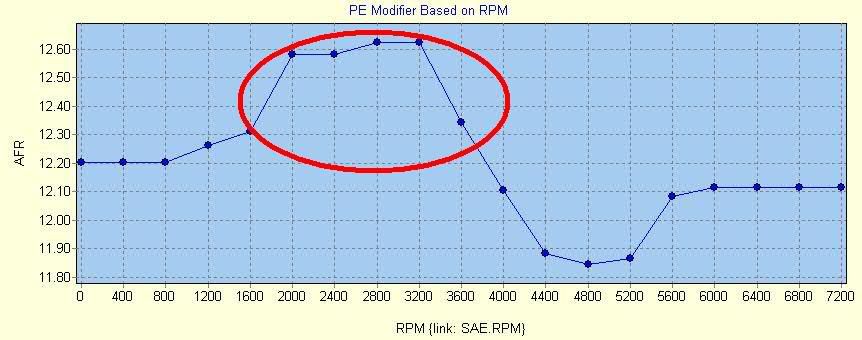

To make the torque curve smoother it looks like they did two things in the region of of the flat. First it looks like they leaned out the commaned AFR curve in the PE curve.

Z06 PE curve - Note the area circled in red. You can see they leaned it out in the range of the VE/torque flat.

It also looks like GM added some timing in that same range.

Z06 Timing Map - Note the hump at the top of the "hill"

How does this relate to people with big cams.

Here is my PE table, which I think is plenty "lean" in that location of the dip, so I don't think I'll change anything there.

Reply With Quote

Reply With Quote